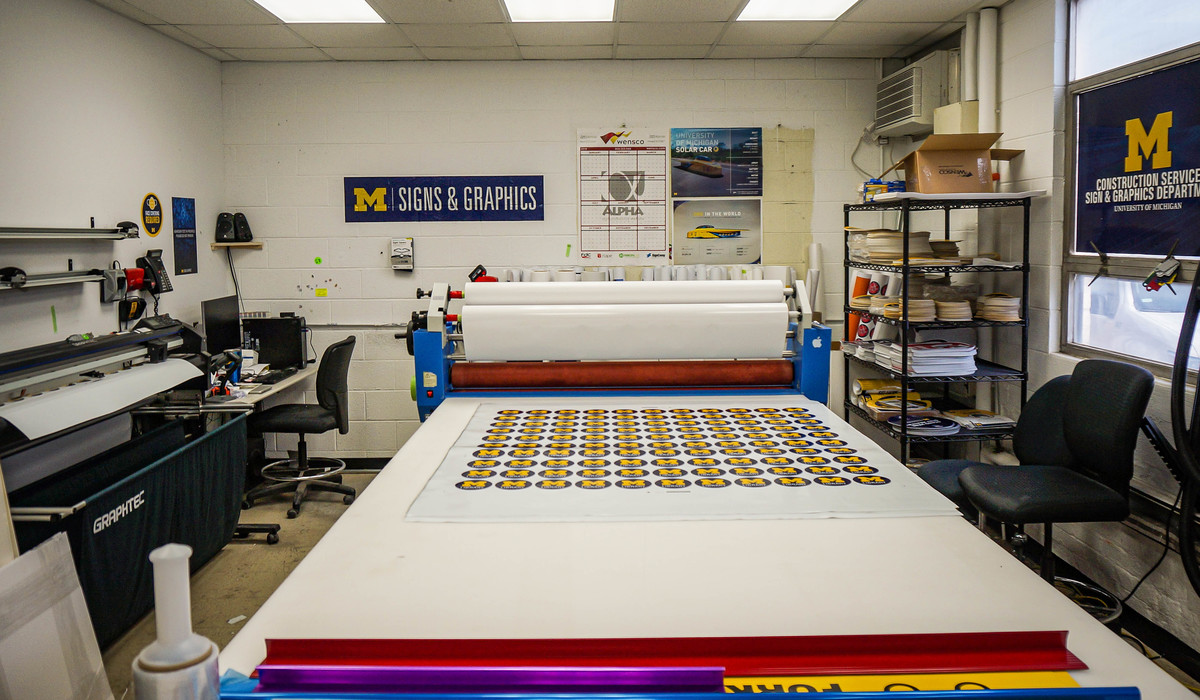

In the months leading up to the reopening of U-M this past fall, many University employees were hard at work trying to ensure the safe return of students, staff, and faculty. Few, however, may have worked as hard as Dustin Gilbert and his co-workers Nick Scott and Matt Wilson. From mid-March to May, the three could not enter U-M’s Sign & Graphics Shop, where they work, due to COVID-19 closing down campus. Then, upon their return, they faced numerous work orders for the pandemic. “We worked seven days a week, for six weeks straight,” recalls Gilbert. “I would estimate we did more than 100,000 pieces around COVID-19,” says Gilbert. What’s more, they did it all in a two-room space of just 962 square feet.

The team made barrier signs, acrylic dining hall sneeze guards, glass enclosures, and all the signage on building entrances and outdoor study areas that outlined pandemic rules and regulations. Located in the Plant Services Building, the Sign & Graphics Shop is part of the University’s Architectural Engineering & Construction team. The building also houses other trades like cabinetry, furniture and upholstery, and the glass shop.

Of all the pandemic pieces the team created, Gilbert is most proud of the floor decals all over campus advising people where to stand safely for social distancing. Under pressure to get them produced and installed quickly, the sign makers created the decal’s design. That design, modified slightly, became part of the cohesive sign package produced by Michigan Creative, U-M’s branding and marketing agency, and U-M’s team of Environment, Health & Safety. “We were really proud that they liked our design that much,” he says.

Gilbert admits that making all the signage for the University’s bicentennial three years ago was also a lot of work between the banners they created to hang on buildings and the flags and signs they produced for large events. There was, however, one big difference. “We could plan for that work,” says Gilbert. “COVID was completely different.”

Located on Hoover Avenue, the building has a long history of housing hard workers. Before the University bought it in 1956, it was the Hoover Ball Bearing Plant. In those early signage days, there was only one sign maker who hand-painted the names of professors and room numbers on glass and wood office doors (some can still be seen in Hutchins Hall).

When Gilbert started working in the shop eight years ago, it had only one small printer and a rotary engraver. Gilbert — together with Wilson and Scott, who joined shortly after the shop’s three predecessors retired — decided to bring the shop into the modern age. Today, they have lasers and printers that can cut acrylic, print on vinyl, and create Braille tactile signage to be compliant with the Americans with Disabilities Act (ADA). “All classrooms and accessible spaces, like kitchens and restrooms, have to be ADA compliant,” explains Gilbert.

In normal times, their workload consists of making anywhere from 80 to 200 signs per building and doing display work for new or renovated buildings. Recently, they made 85 signs for the renovated Alumni Center.

Ironically, the one thing Gilbert says he yearns for is signage for his shop. “We need an office display showing our portfolio of products with photos. Right now, people just have to look at our Google drive,” he says. “We just don’t have space.”